(A)dvanced (R)ugged (T)echnology

We invite you to delve into the limitless possibilities of ART transistors. Their remarkable durability, precision, and efficiency have made them an indispensable force in shaping our modern world, from driving innovation in microchip manufacturing to fueling breakthroughs in sustainable energy solutions. The future is powered by Ampleon's ART transistors – be part of the transformation.

Ampleon's ART transistors are specifically engineered to deliver the best in terms of RF power, gain and efficiency, but more importantly, they boast crucial ruggedness and reliability features that set them apart from the competition. These vital features serve as a cornerstone of our product's capabilities. It is, without a doubt, one of the fundamental elements that make our product a standout choice for users seeking the highest level of performance and value under the harshest impedance mismatch and power cycling conditions.

It comes as no surprise that ART transistors have quietly emerged as the driving force behind modern technology and innovations. In today's landscape, they can be spotted across a wide range of applications, acting as RF sources in plasma generators, powering CO2 laser systems, contributing to fusion power reactors, and enabling the next generation of magnetic resonance imaging (MRI) scanners.

Here are a few instances demonstrating how ART transistors have woven themselves into the fabric of our daily lives, quietly but significantly impacting the way we live, work, and connect in our ever-evolving society.

Advanced microchips

ART power transistors play a crucial role in plasma generation and CO2 laser drivers for semiconductor

manufacturing, offering several key benefits. These transistors provide high-frequency amplification and

power capabilities, enabling efficient and precise control of plasma discharges and laser output. Their

ability to operate at radio frequencies allows for rapid switching, which is essential for generating

and maintaining stable plasma in semiconductor processing equipment. Additionally, ART transistors are

highly reliable, with excellent thermal performance, ensuring consistent and long-lasting operation in

demanding manufacturing environments. This reliability not only enhances process efficiency but also

reduces downtime and maintenance costs.

Overall, ART transistors are integral components in semiconductor manufacturing, facilitating the

production of high-quality microelectronics through their contributions to plasma generation and CO2

laser drivers. This will help address global challenges and transform the way we work, live, and

interact with the world around us.

Photovoltaic

ART transistors, employed in microwave annealing processes, hold a dual significance in both the

manufacturing and recycling of solar panels. In the manufacturing phase, these transistors are

instrumental in optimizing the performance of solar cells by precisely controlling the annealing

process. This ensures that the semiconductor materials used in the panels are tailored for maximum

efficiency, ultimately contributing to the production of high-quality and durable solar panels.

However, the importance of RF power transistors does not end there. In the recycling of solar panels,

these transistors play a crucial role in the recovery and rejuvenation of valuable materials. By using

microwave annealing techniques powered by ART transistors, it becomes possible to reclaim and reuse

semiconductor materials from old or damaged solar panels, reducing waste and environmental impact. This

closed-loop approach not only conserves resources but also aligns with the principles of sustainability

and circular economy, ensuring that the lifecycle of solar panels is extended, and their environmental

footprint minimized.

As the world embraces renewable energy solutions, the importance of ART transistors in this context

cannot be overstated. They bridge the gap between efficient solar panel manufacturing and responsible

end-of-life practices, forging a path towards a more sustainable and environmentally responsible future.

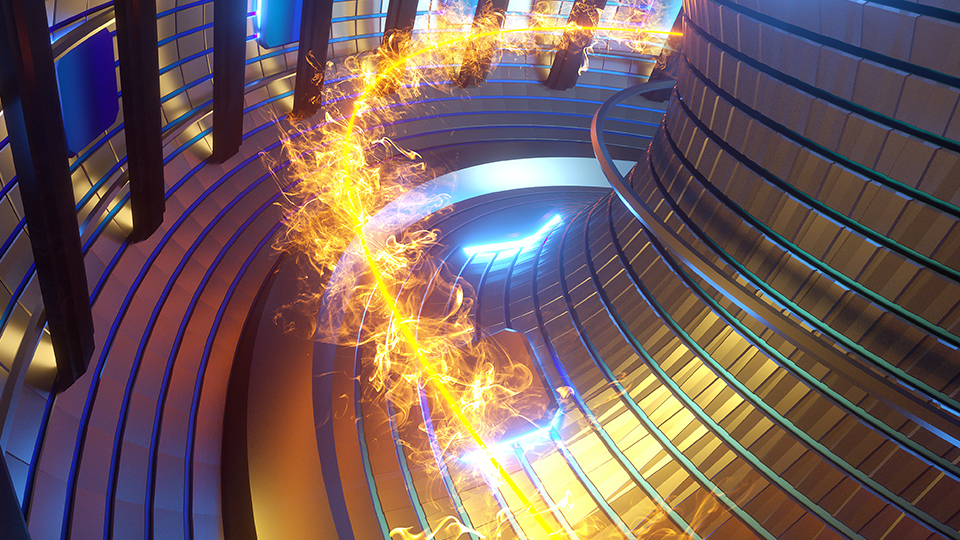

Fusion energy

ART transistors are pivotal components in the development and operation of fusion energy reactors,

exemplifying their critical importance in the quest for clean and sustainable energy sources. They are

responsible for delivering and controlling the RF energy essential for heating and stabilizing the

superheated plasma within a fusion reactor.

By precisely generating and controlling RF energy, these transistors contribute to achieving the

extremely high temperatures and pressures required for nuclear fusion, a clean and virtually limitless

source of energy. The reliability and efficiency of ART transistors are paramount because any

fluctuations or interruptions in the RF power delivery could disrupt the delicate balance of the fusion

reactor, impeding progress toward achieving sustainable fusion energy.

In essence, the ART transistors are catalysts for the advancement of fusion energy, holding the

potential to revolutionize our approach to clean, abundant, and environmentally friendly power

generation, addressing the pressing global need for sustainable energy solutions. By enabling the

maintenance of extreme plasma conditions, the ART transistors contribute to achieving the goal of

virtually limitless and emission-free energy.

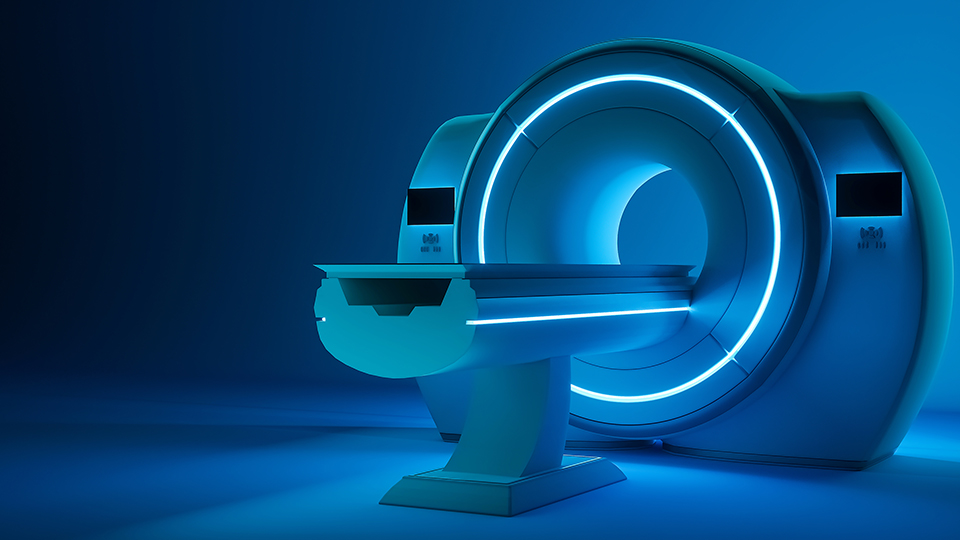

Medical imaging

ART transistors hold a paramount role in the field of medical diagnostics, particularly in the operation

of MRI (Magnetic Resonance Imaging) systems. They are responsible for generating the crucial RF pulses

used to manipulate the magnetic resonance of hydrogen atoms within the patient's body, producing

detailed and high-resolution images of internal structures.

The precision, consistency, and reliability of ART transistors are critical in ensuring the accuracy of

MRI scans, as any fluctuations or interruptions in RF energy can compromise image quality and diagnostic

accuracy.

By enabling the creation of clear and informative medical images, ART transistors contribute to early

disease detection, accurate diagnoses, and treatment planning. This, in turn, empowers healthcare

professionals to provide timely and effective care to patients, making ART transistors indispensable

tools in the realm of modern medical imaging and diagnosis.

Selection of available application boards

Customized application boards are created upon request, tailored to the specific needs of each customer on a case-by-case basis.

|

Frequency (MHz) |

Product |

Application report |

Pout (W) |

Efficiency (%) |

Gain (dB) |

|

2 |

1300 |

80 |

20 |

||

|

13 |

AR211135* |

1005 |

90 |

29.6 |

|

|

1600 |

76.5 |

29.6 |

|||

|

27 |

1160 |

90.7 |

29.1 |

||

|

725 |

75 |

21 |

|||

|

41 |

1600 |

78.5 |

28 |

||

|

900 |

89 |

26 |

|||

|

172 |

85.1 |

30 |

|||

|

60 / 64 |

AR201093* |

1788 |

84.7 |

28 |

|

|

81 |

1393 |

81.3 |

19.7 |

||

|

88 - 108 |

1490 |

82.6 ~ 84.7 |

24.2 |

||

|

128 |

AR221142* |

2380 |

78 |

26.6 |

|

|

352 |

AR201023* |

1500 |

74 |

20 |

* For access, please contact our local sales representative via: www.ampleon.com/contact

Competitive benchmarking

|

Product |

BLF188 |

BLF189 |

ART1K9 |

ART2K0 |

ART2K5 |

1K25 |

1K5 |

1K80 |

MQ012K0VPX |

RF5L02K0CF4 |

HTH8G02P1K4H |

|

Technology |

LDMOS |

||||||||||

|

Package |

ACC* |

ACC and OMP** |

ACC and OMP |

ACC |

ACC |

ACC |

|||||

|

Vds (V) |

50 |

50 / 55 |

65 |

75 |

50 |

65 |

50 |

55 |

50 / 55 |

||

|

Min. BVdss (V) |

135 |

177 |

203 |

203 |

133 |

135 |

179 |

140 typ. |

110 |

135 typ. |

|

|

Output Power P1dB (W) |

1400 |

1700 |

1700 / 1900 |

2000 |

2500 |

1250 |

1500 |

1800 |

2000 |

2000 |

~1200 / ~1400*** |

|

VSWR |

65:1 |

65:1 |

65:1 |

n.a. |

10:1 |

65:1 |

|||||

* ACC: Air Cavity Ceramic

** OMP: Over-molded Plastic

*** Converted from the output power figures at Psat as given in the product data sheet

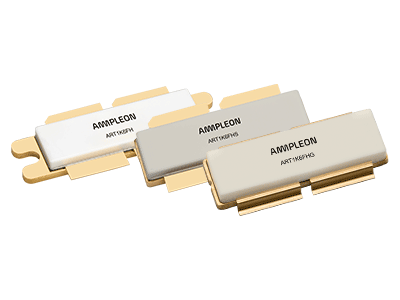

Featured products

Committed to your success

During the entire process from design to delivery, we provide a range of support options to address your needs. Whether you require load-pull data, application boards, samples, ADS / AWR models, assistance with a complex design challenge or seek quick advice, we are on stand-by to support you. Our application engineering resources are spread around the globe, with our offices in Nijmegen / The Netherlands, Toulouse / France, Smithfield / USA, and Shanghai / China.